ABOUT the SUPER STONE.

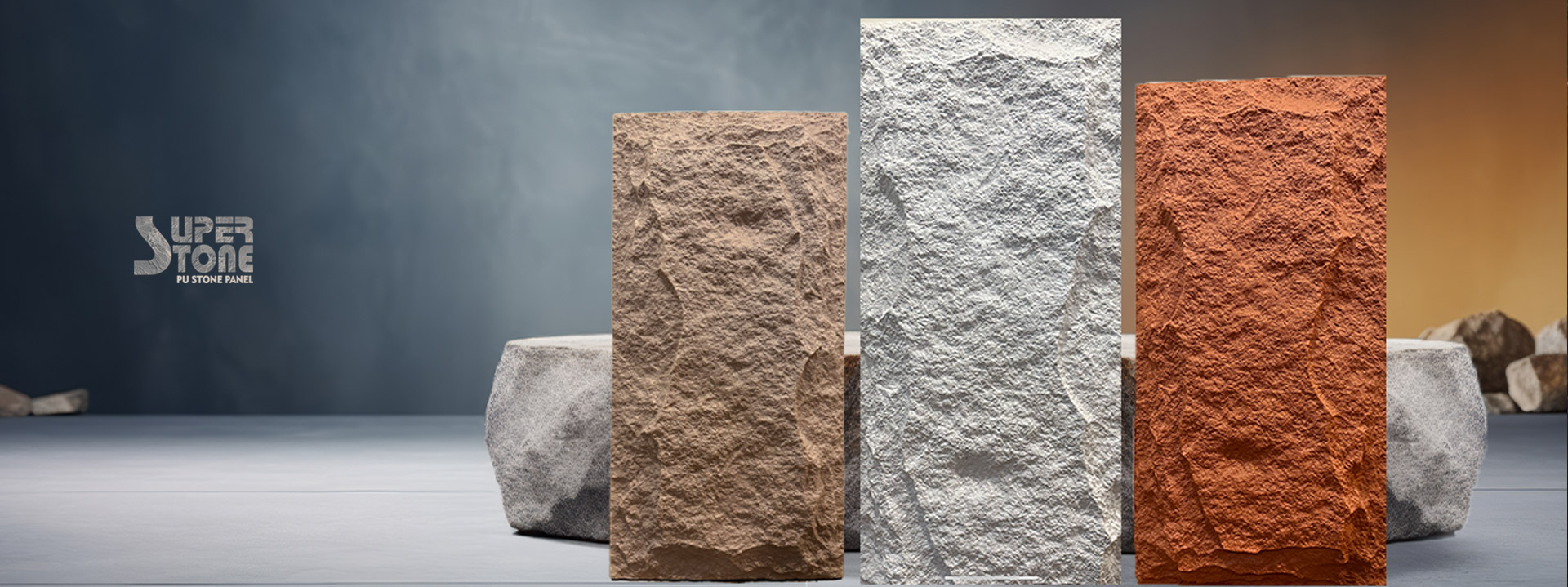

Super Stone board is the 1 & ONLY PU Stone Board Manufacturer in India with different patterns & designs.

SuperStone Panels are made ofHigh densitypolyol technology. It's very light in weight, but strong and durable. Unlike 100% real stone which are heavy and mineral composite manufactured stone; Super stone sidings are 1 lbs per square feet, less than 1/10 weight of natural stone or manufactured stone.

Super Stone Panels are easy to cut with a conventional hand saw and can be easily installed by screws. Installing faux stone for exterior as stone siding or interior stone wall, we do not need any mortar, just normal screws. DIY-friendly lightweight; Super stone boards are good forretails oron-line shop.

Panelized design makes installation go faster than individual stone. No need of mortar to fit all individual pieces together, saves much time and labor-cost forinstallation.

As exterior use faux stone siding, ourpanels are certified by ASTM-G155 UV resistant, ASTM-E330 Wind resistant and ASTM-D6413 / D6413M fire resistant tests.

Casting from the real stone and hand-painted texture, our Super Stone Panels are realistic, similar to actual Stone with close look and it is much better than other simulated stone vinyl siding, plastic stone siding which with ametal layer, foam core.

FEATURES OF SUPER STONE .

It is a safe material option to install in and around your fireplace, so you won't have to worry about any wall damage happening unknown to you.

Super stone has a layer of self-developed coating, with waterproofand flame retardant functions.

Super stone is made of PU as the main material, and anticorrosion polymer materials are added, and the weight per panel is only 3 kg approx for 8 sq.ft. Since Super stone is made of high-tech materials, it is light in weight and does not require the cooperation of other machinery, and can be installed byasingle person.

PU stone integrates the advantages ofan external thermal insulation system and has thermal insulation function.

The Super Stone style can be adapted to random designs, with strong texture and various shapes, and can be customized according to special requirements.

PU stone adopts prefabricated installation or matching glue to bond to the wall, with high safetyfactor.

The temperature resistance of Super stone is minus 20 degrees - high temperature 120 degrees.

INSTALLATION PROCESS OF SUPER STONE .

Treatment of the grassroots

Step 1

Wipe the leveling layer

Step 2

Step 3

Paste Super Stone

The Super stone should be inlaid from bottom to top, and the bonding thickness should be between 20 and 50mm.

Step 4

Pointing

Step 5

Clean the surface

Step 6

APPLICATION OF SUPER STONE .

- On the basis of light weight and firmness, Super stone can withstand all kinds of grinding: it can be nailed, sawn, washable, etc.

- As a cross-border material, PU stone has its own characteristics that make it appear and widely used In the wall decoration of dierent scenes in the interior.

- Now Super stone has been widely used in airports, hotels, building materials, automobile factories, coal mines, cement factories, high-end apartments, villas, landscaping, colored stone art, parks, etc.

- In the living room, Super stone is used as an indoor TV background wall. Its malleability enables it to replace cultural stone and adapt to various styles and colors, bringing asense of design to the space.

- In the bedroom, the bedside background wall of the bedroom is also decorated with Super stone, which brings a more natural and calm rest environment while decorating the wall.

- In the study room, the scholarly study space is the collision of diverse knowledge and diversity, and the wall shape endows the space with more possibilities.

- In the bathroom, the dark bathroom is matched with the PU stone with its own three dimensional texture, which shows the dark and glamorous texture vividly.

- The use of mixed materials in contemporary art is not only more and more common, but also has infinite possibilities to represent future trends